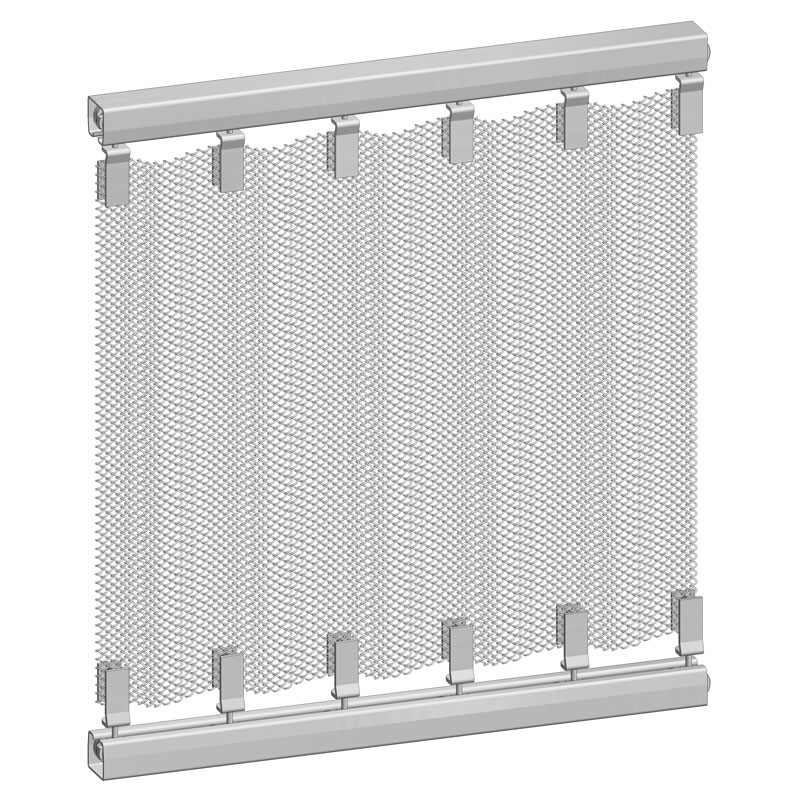

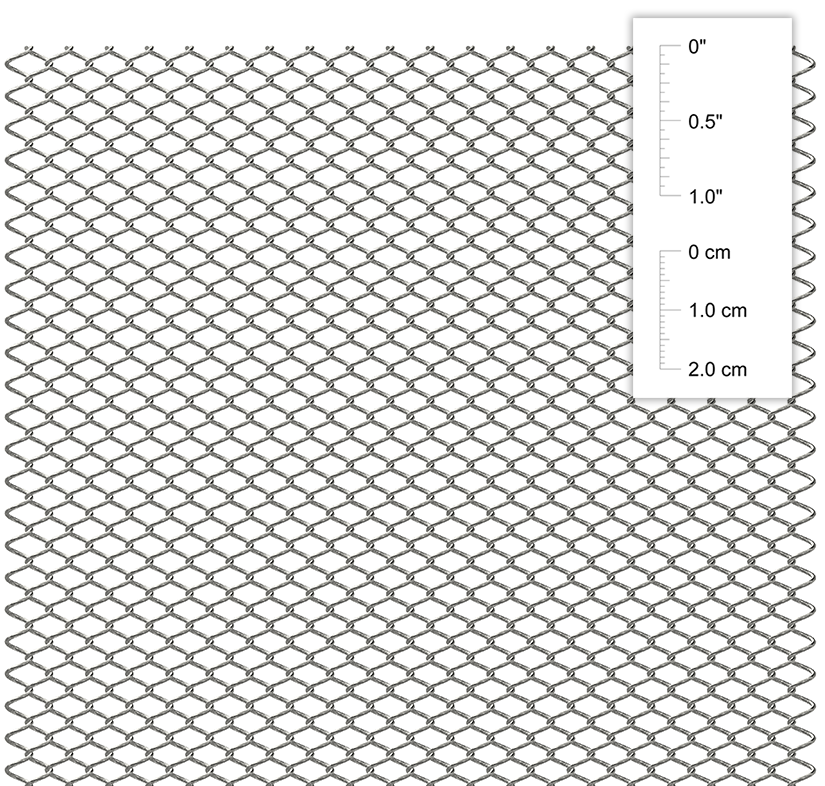

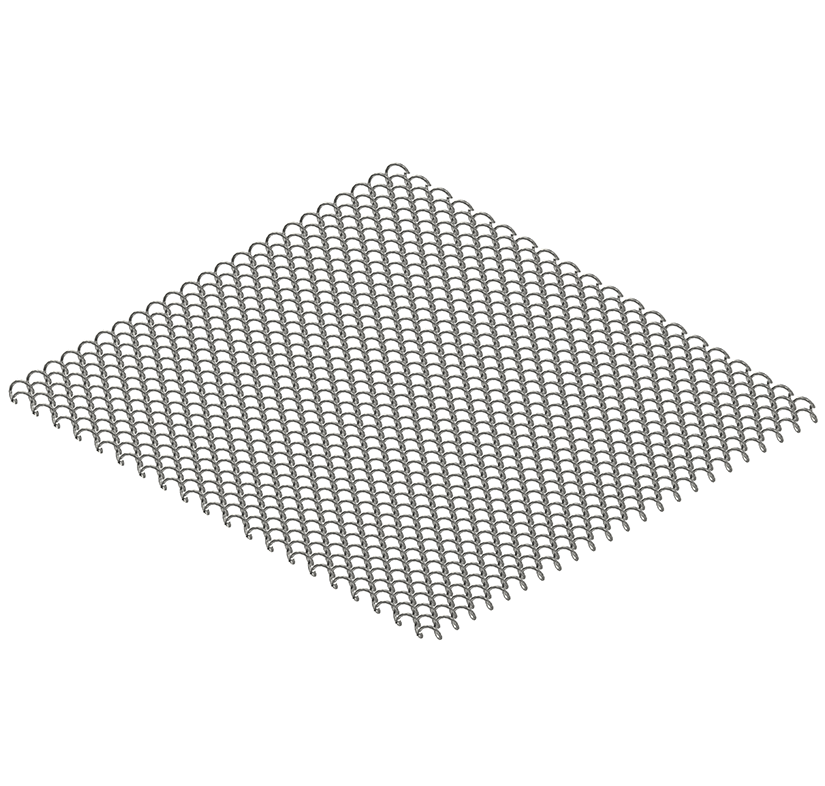

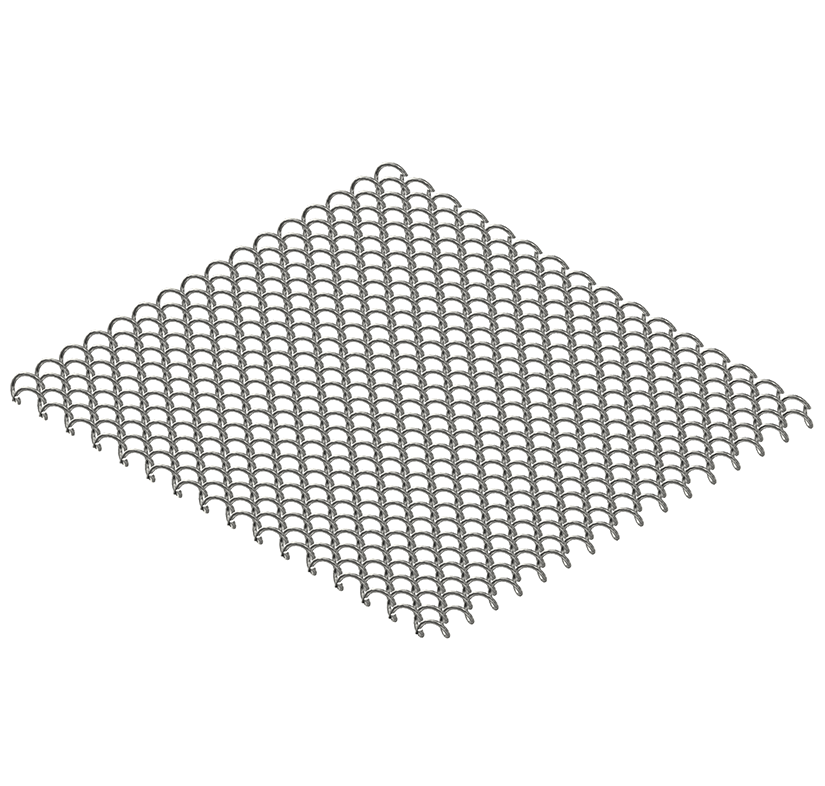

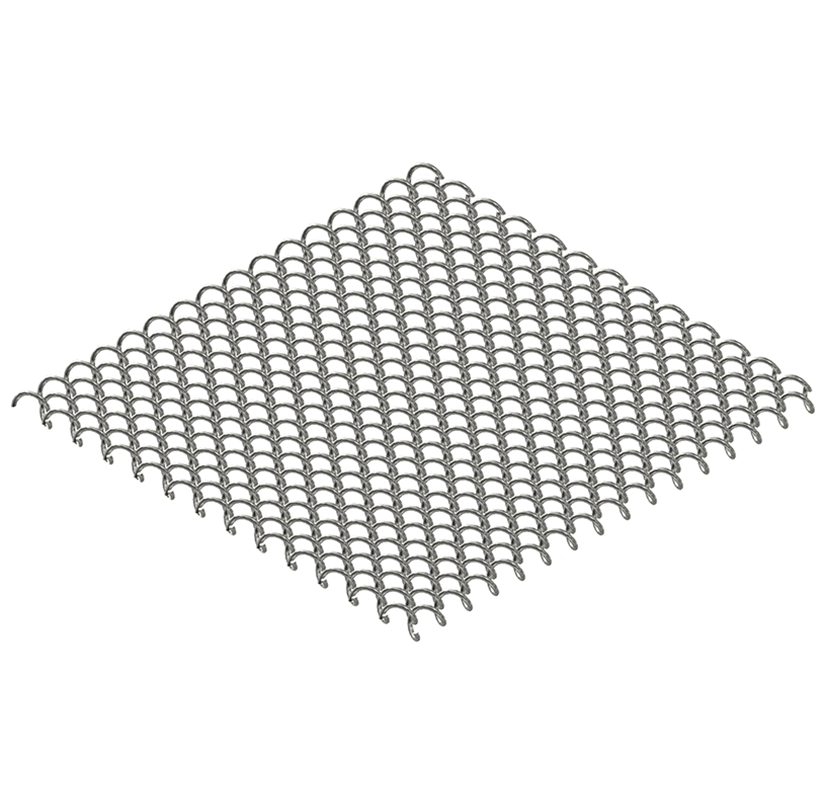

Cascade Industrial Safety and Security, a division of Cascade Coil, is the international leader in the manufacture of coiled wire fabric systems for a variety of new and retrofit industrial safety and security applications.

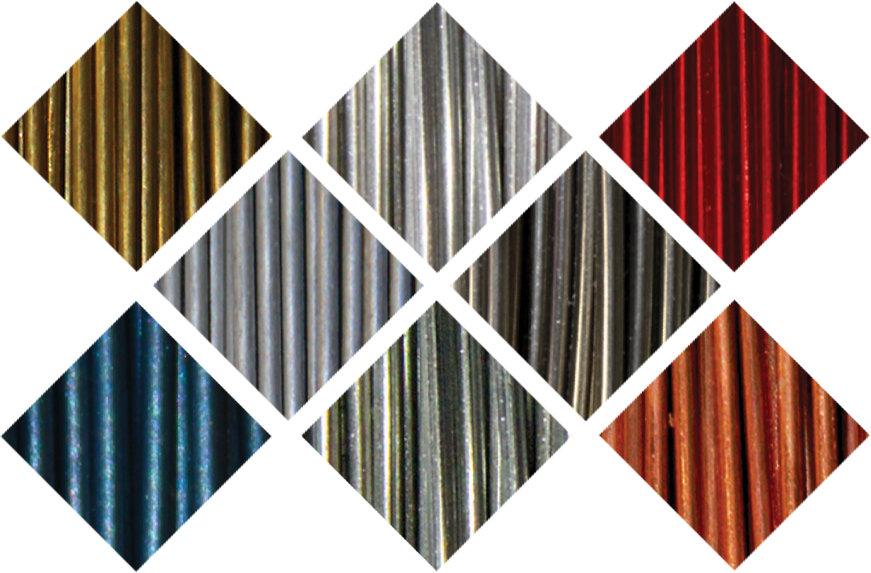

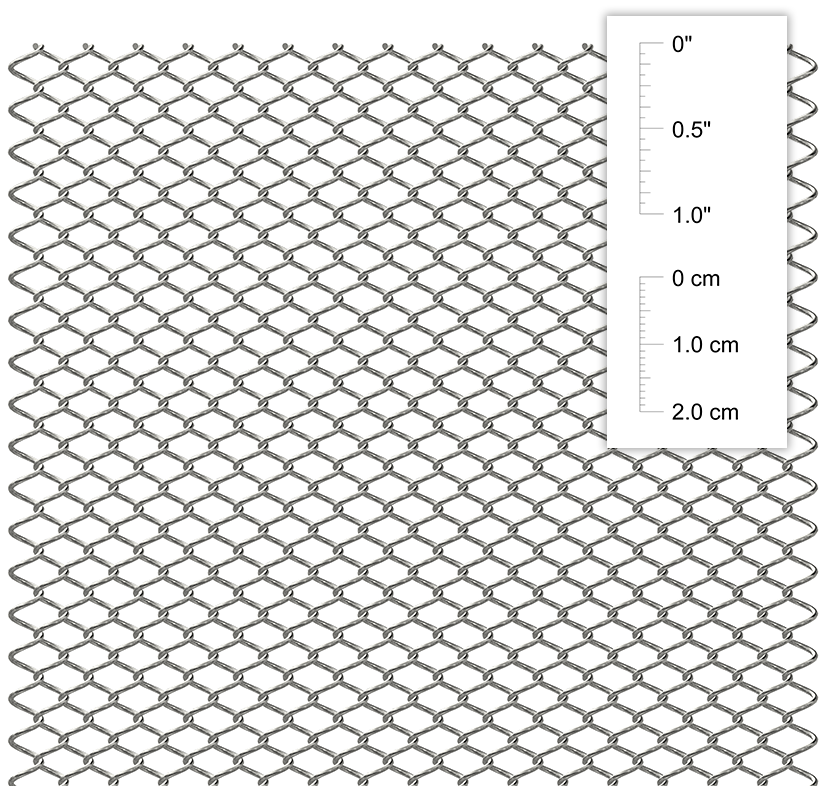

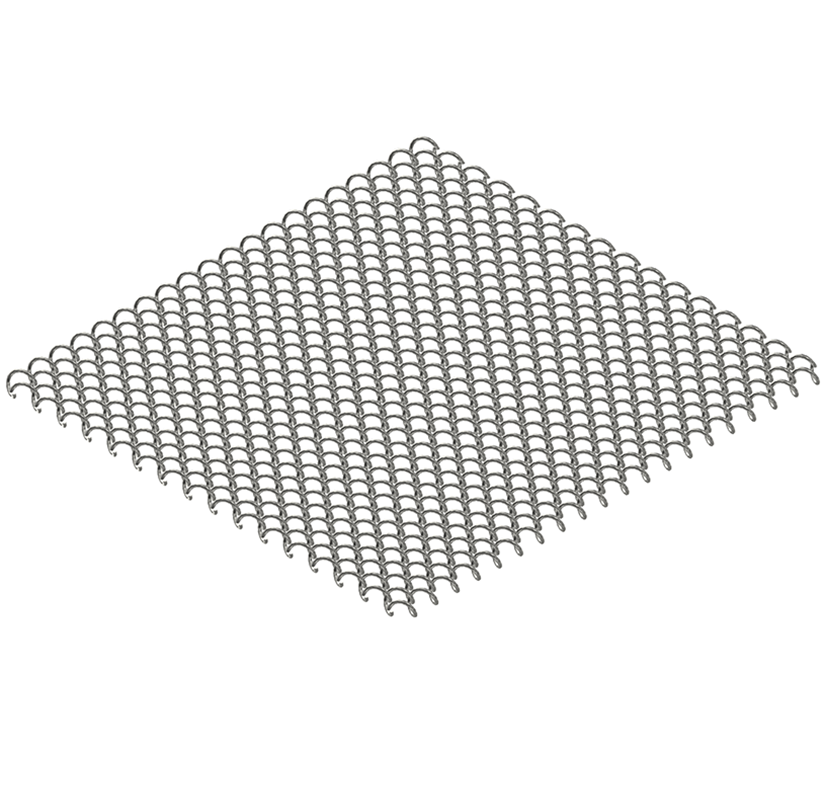

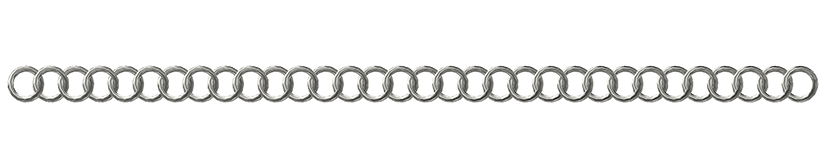

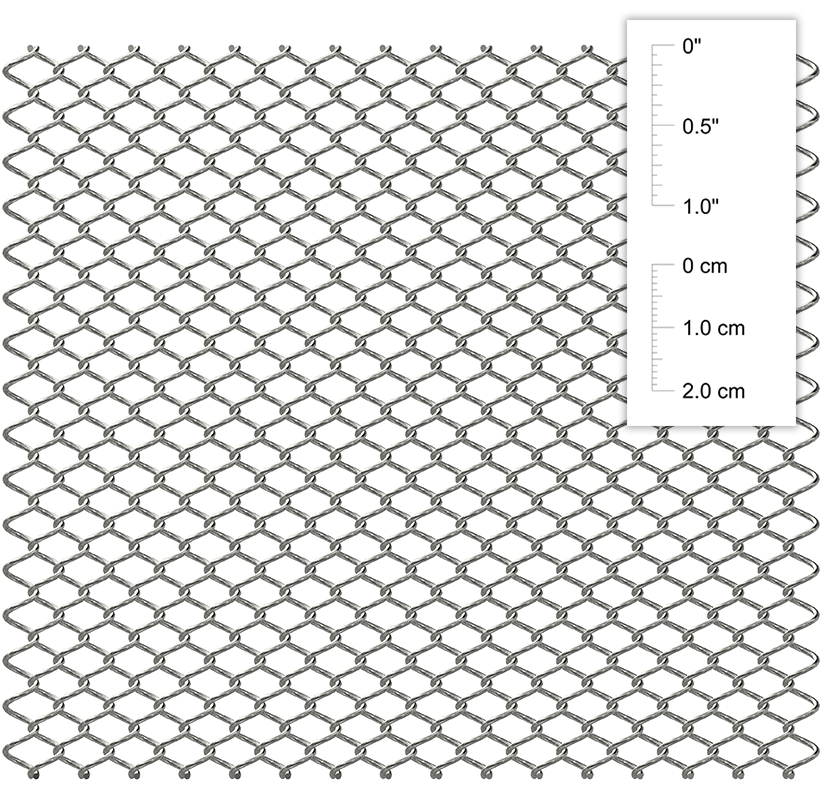

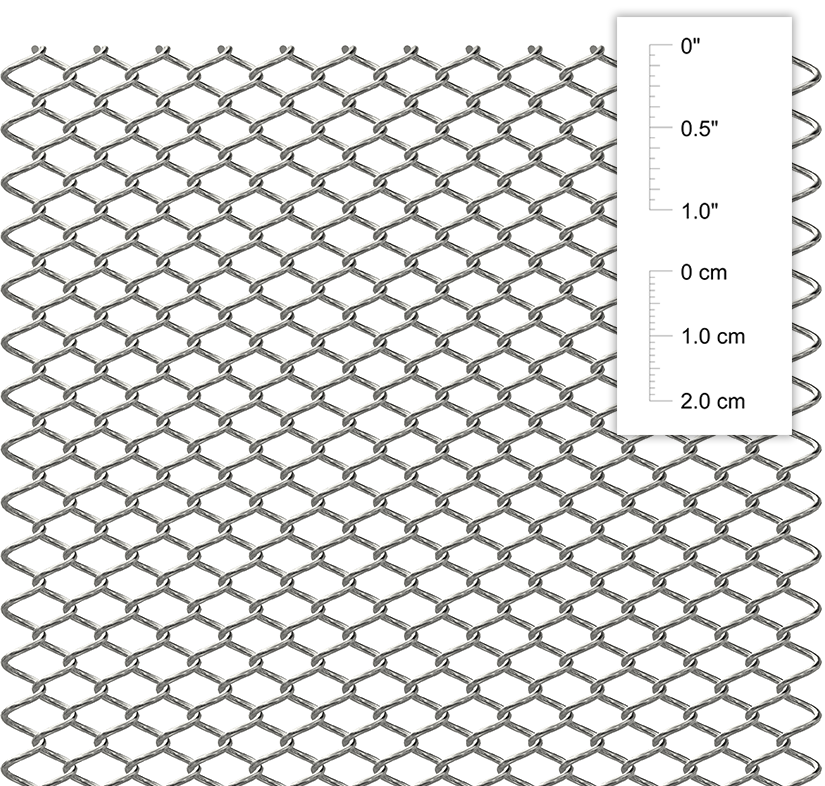

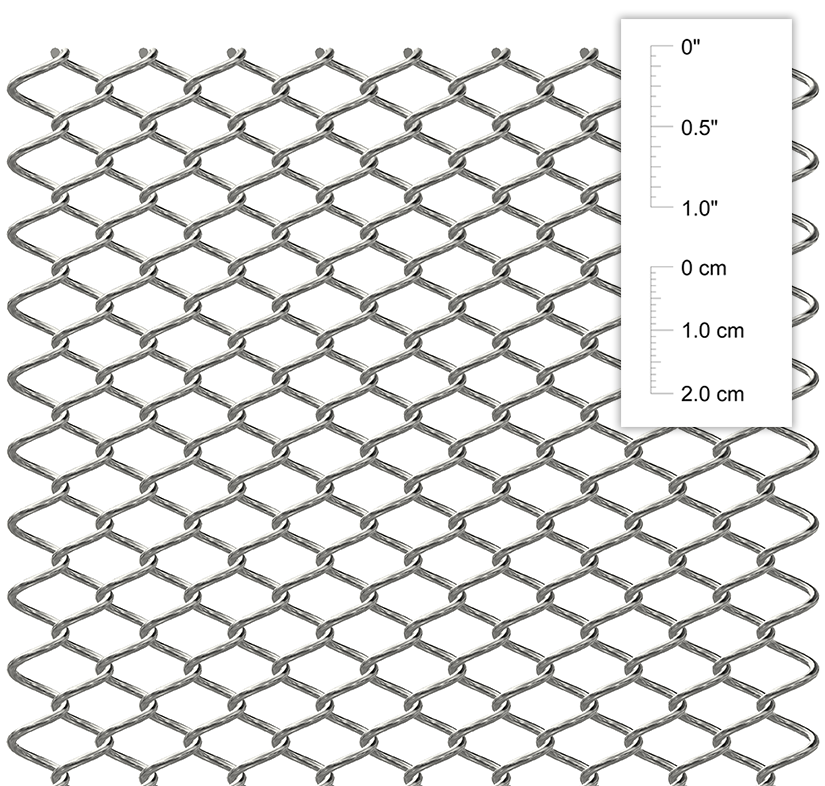

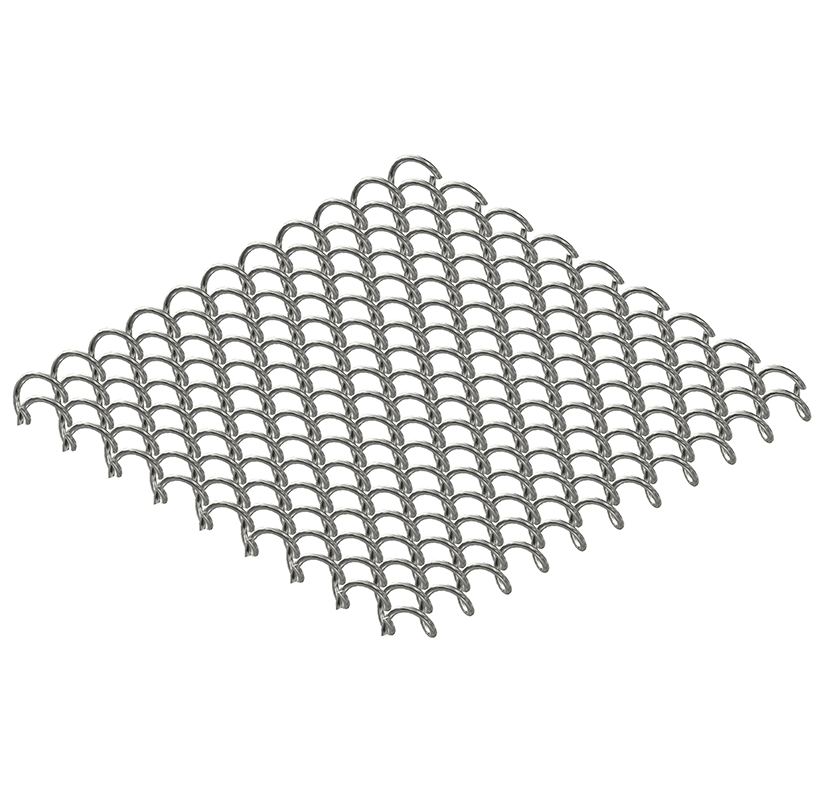

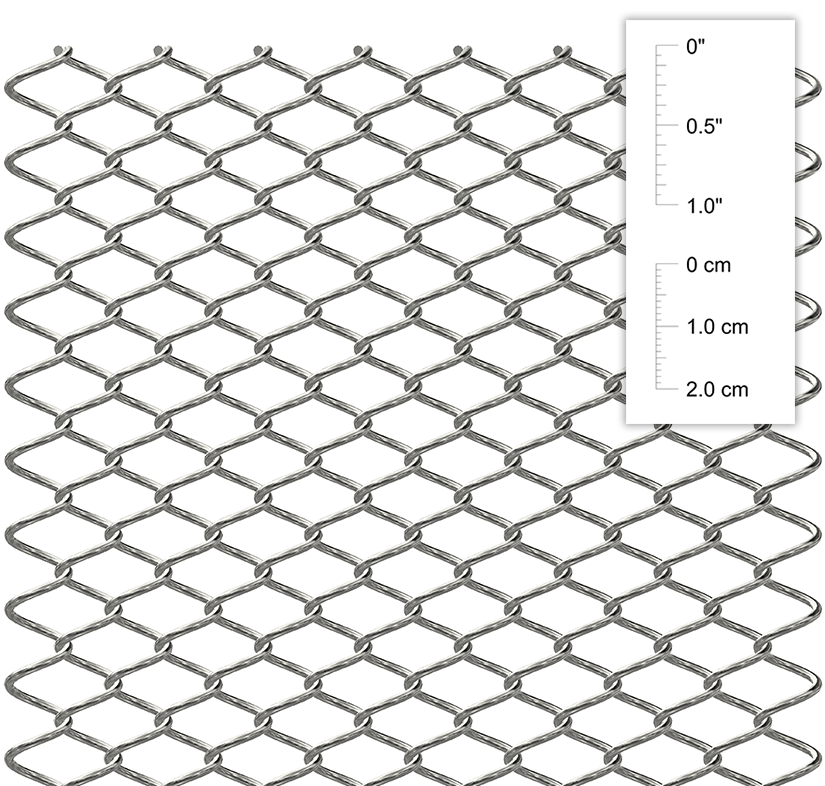

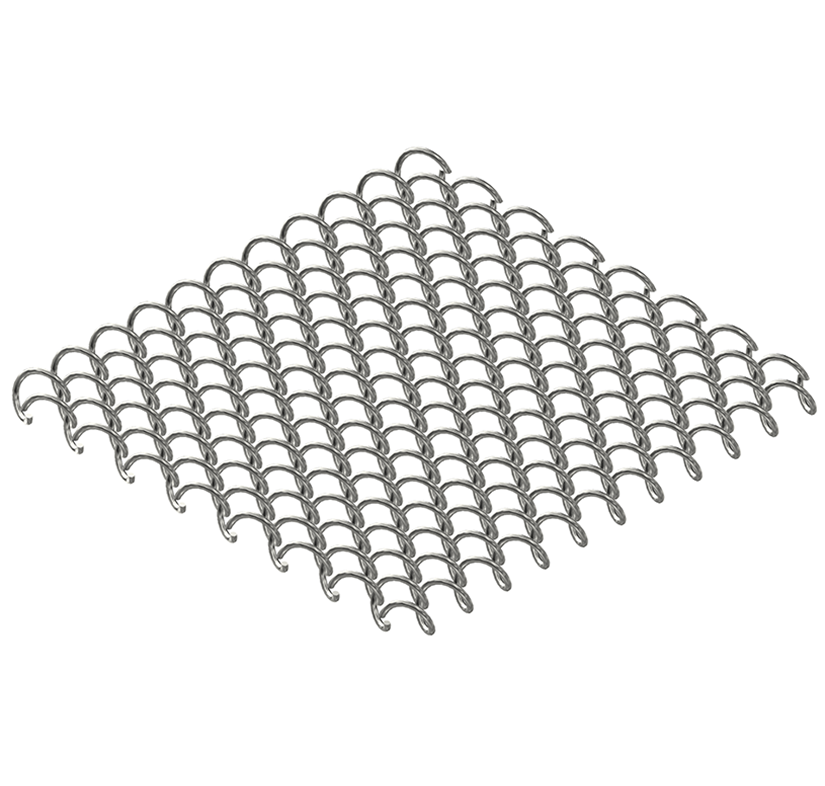

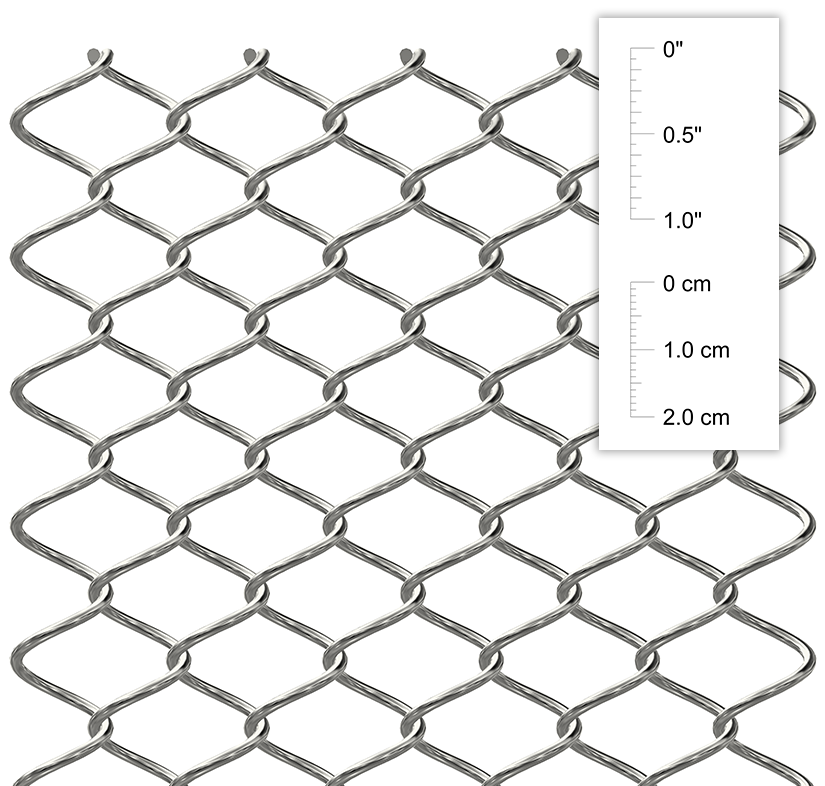

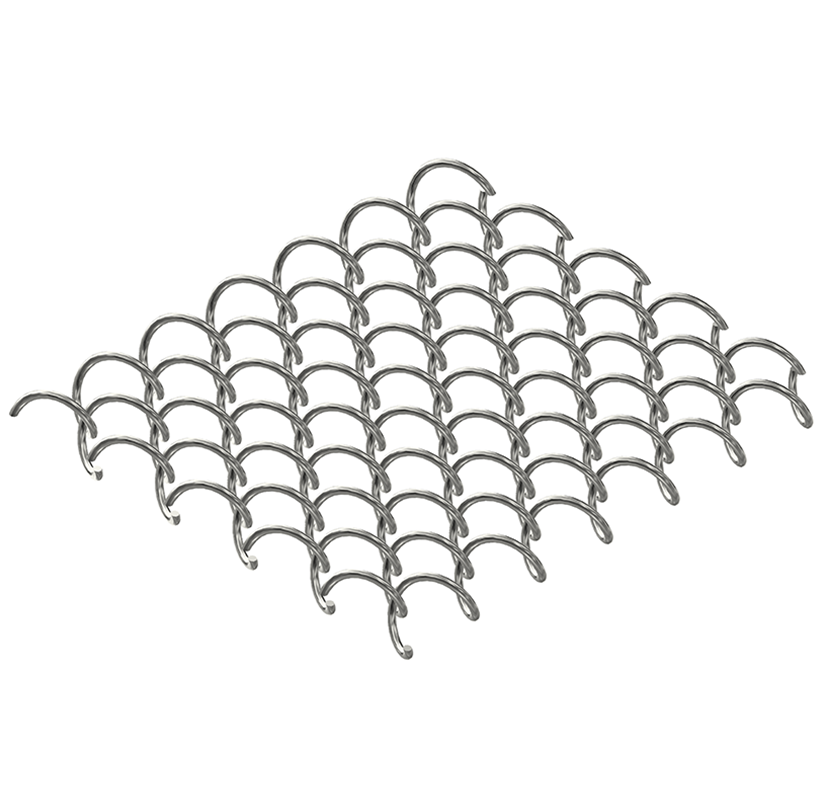

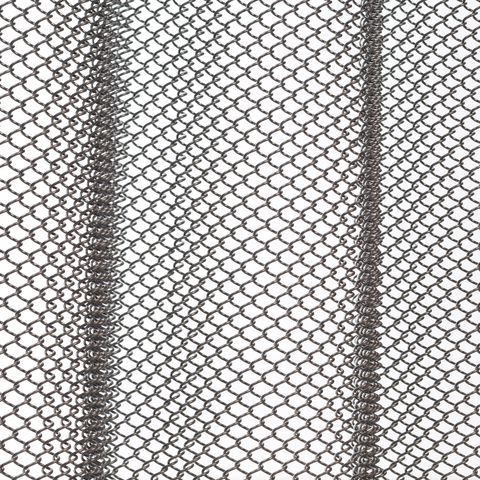

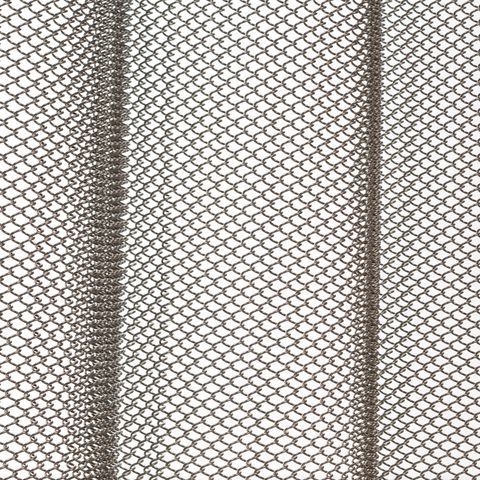

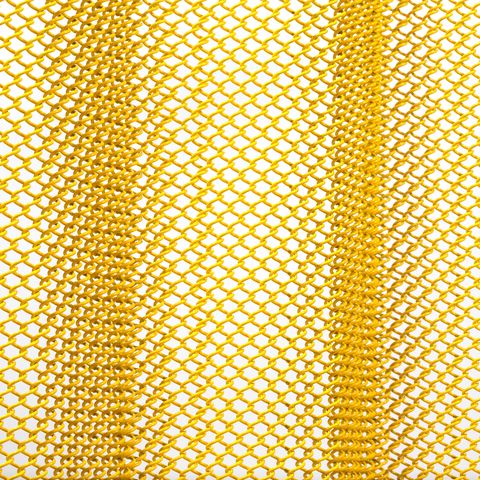

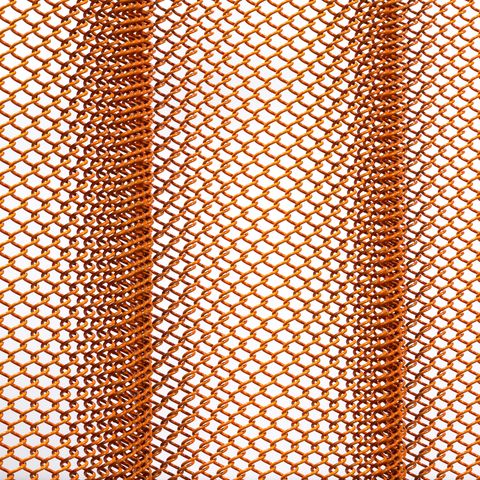

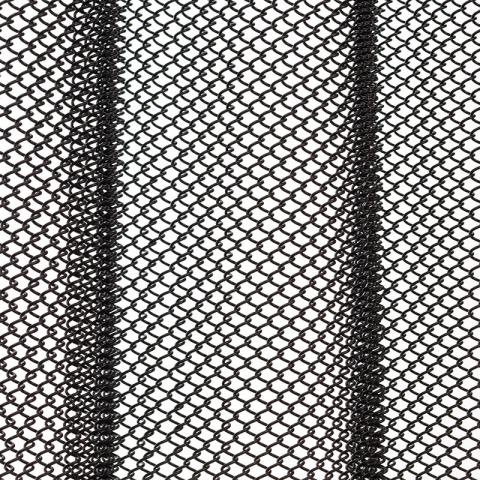

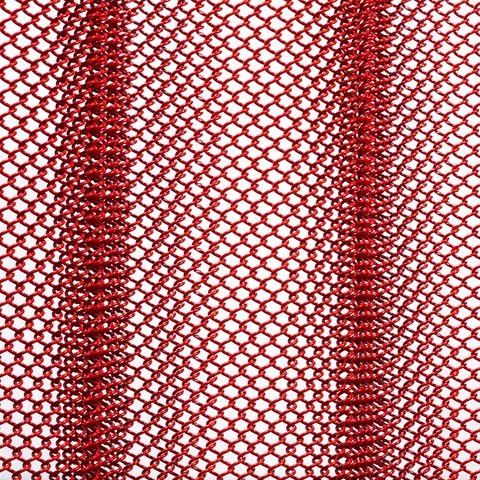

Send us your project detailsMaterials